Shop Our Products

Electrical Equipment From The World’s Top Brands

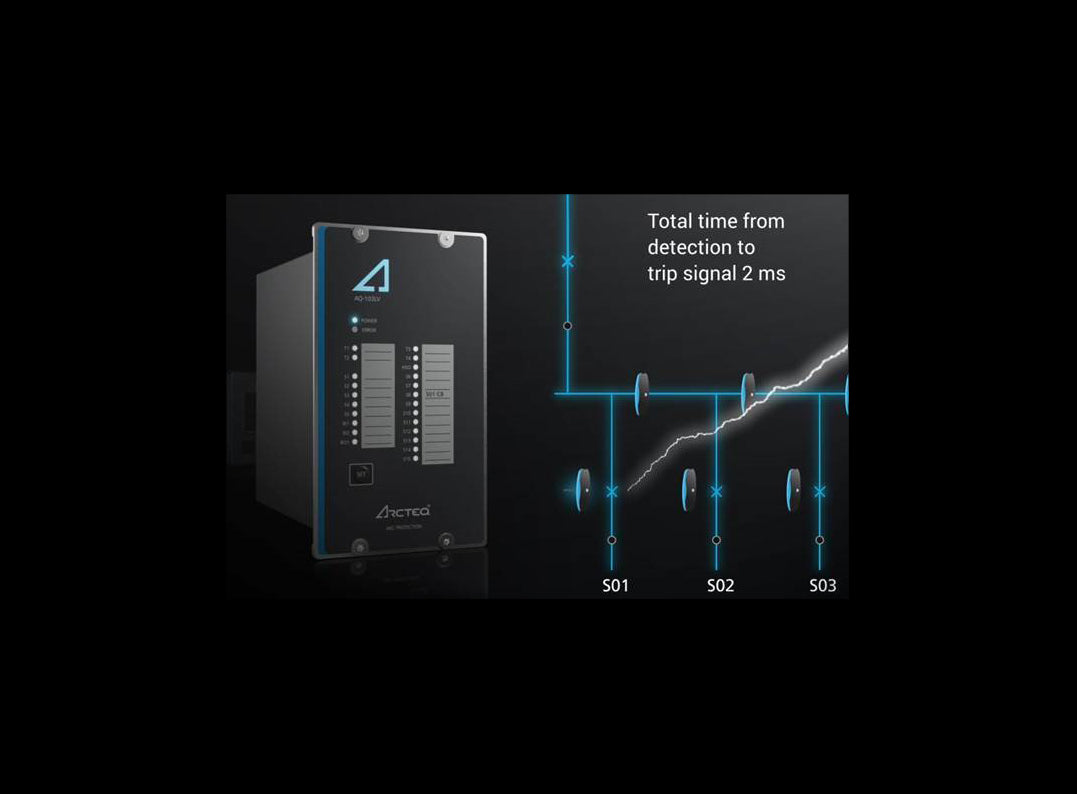

At Leading Edge Sales, we represent the top electrical equipment manufacturers in the world. Our brands span 3 main categories - Electrical Infrastructure, Asset Management and Preventative Maintenance, and Electrical Testing Equipment. We offer a variety of product lines under each brand to meet our client’s needs.

About Our Team

Powering Innovation Through Premier Electrical Equipment Solutions

Our customers are Electric Generators, both Utility and Co-Gen, Transmission and Distribution Utilities and Large Industrial Facilities and their electrical infrastructure. We provide professional representation for Original Equipment Manufacturers (OEMs) worldwide who want to market their products in Western Canada.

Show

-

Brands

23 -

Years of Experience

50 -

Products SKUs

1000++

Let Us Be Your Resource

Offering Tailored Advice & Electrical Equipment Solutions For Your Company

At Leading Edge Sales (LES), our mission is to provide unparalleled service and support as we represent the leading manufacturers of electrical equipment globally. Our extensive range of products covers three primary categories: Electrical Infrastructure, Asset Management and Preventative Maintenance, and Electrical Testing Equipment. We take pride in offering an array of exceptional product lines within each brand, ensuring that we meet and exceed our clients’ individual requirements.

Working with LES offers numerous selling points that set us apart from the competition. First and foremost, we prioritize customer satisfaction and strive to build long-lasting partnerships. Our dedicated team of experts possesses deep industry knowledge and is committed to delivering tailored solutions that address specific challenges.

-

Fast Response

We believe in open and rapid communication

-

Knowledgeable

Get detailed and tailored answers to your questions

-

Secured Payment

100% secure online payments for all online purchases

Testimonials

A Word From Our Clients

Our customers span the Utility, Industrial, Institutional end users, and equipment integrators and HV services groups. We strive to support all our customers and suppliers with timely, thorough, exceptional customer service.

Button label